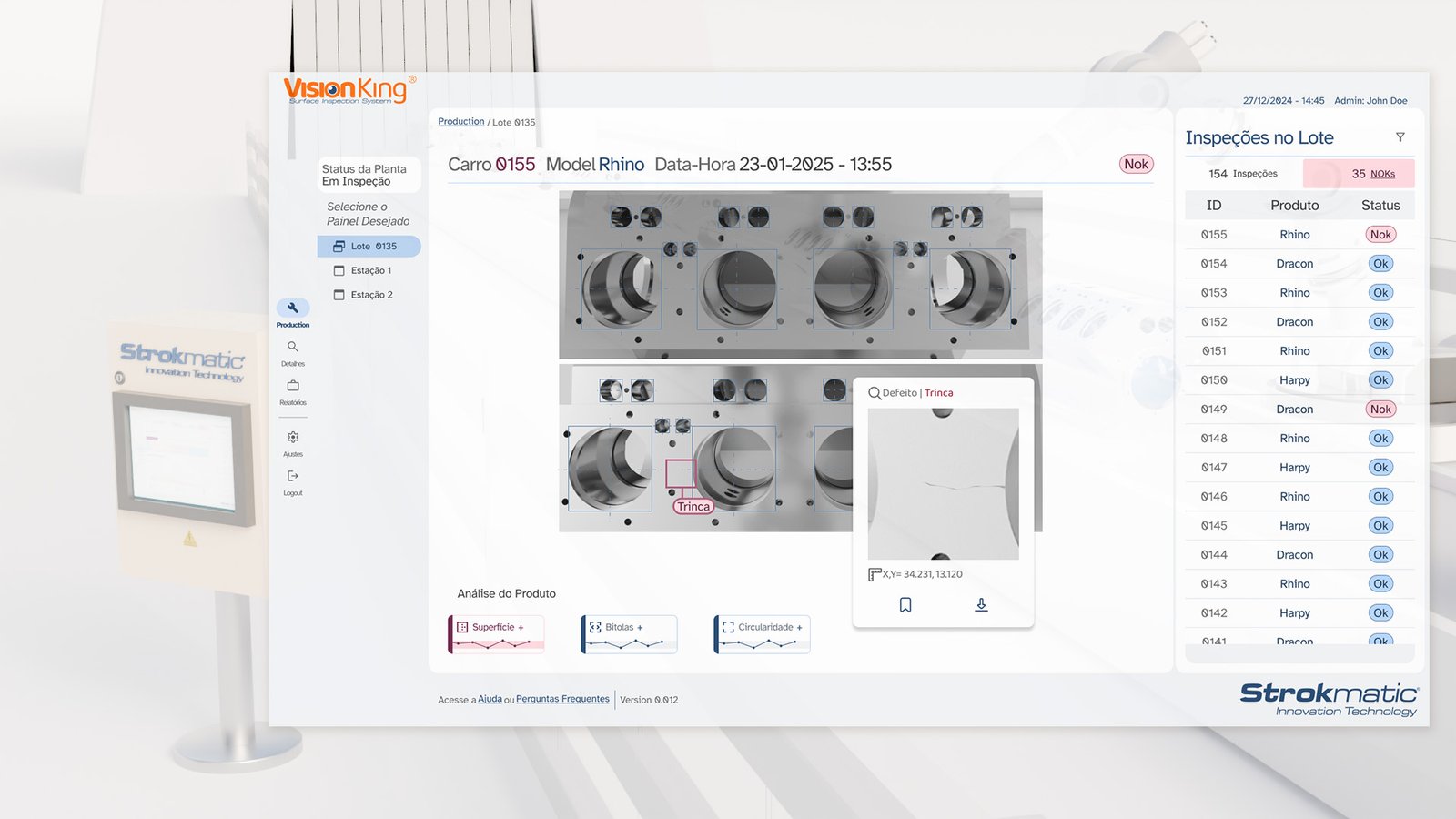

The main objective is to identify defects, imperfections, and assembly errors such as the shape and presence of holes and chambers in cast and machined parts, along with the position and integrity of crucial components, including:

Technology Description

Pin Holes

Roughness

Scabs

Sand Inclusions

Swells

Micro Shrinkage

Slag Inclusions

Blow Holes

Computer vision applied to engine inspection has become an essential solution for ensuring quality in vehicle manufacturing processes. Vision King utilizes cameras and image processing algorithms to detect defects, irregularities, and specific characteristics in the engine’s structure and assembly that are difficult to identify with the naked eye.