Vision King – Final Assembly

Technology Description

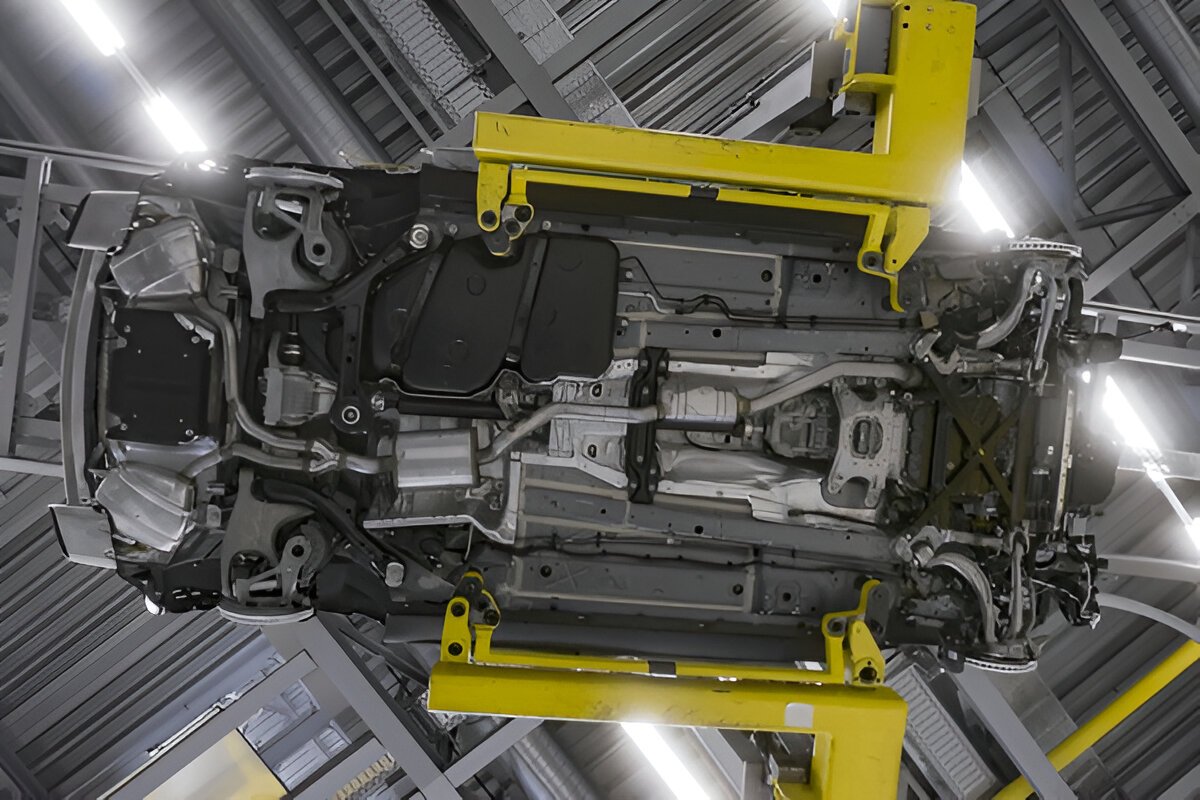

Enables automated visual inspection, ensuring accurate identification of the positioning and assembly of dozens or even hundreds of components across various parts of the vehicle, fully integrated into the production line.

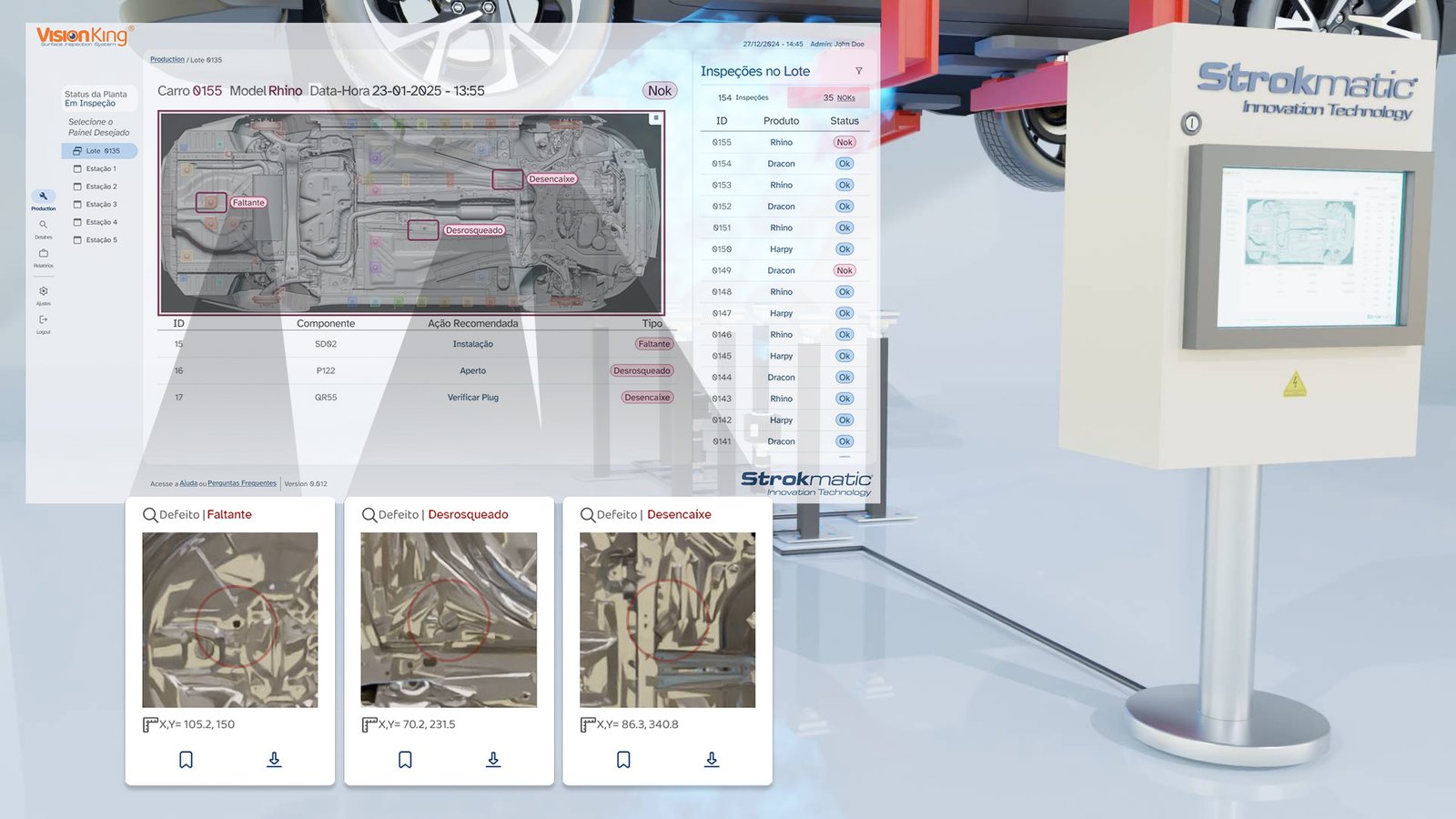

Loose Parts

Irregular Positioning

Disconnections

Swapped Sides

Missing Parts

Computer vision applied to component assembly inspection has become an essential solution for ensuring the quality of product delivery. Vision King utilizes cameras and image processing algorithms to detect defects, incorrect positioning, and omissions that can go unnoticed by the naked eye.

Computer vision applied to component assembly inspection has become an essential solution to ensure the quality and compliance of industrial products. Vision King integrates high-resolution cameras, dedicated lighting systems, and advanced image processing algorithms to detect defects, misalignments, and missing components that would otherwise go unnoticed by the naked eye.