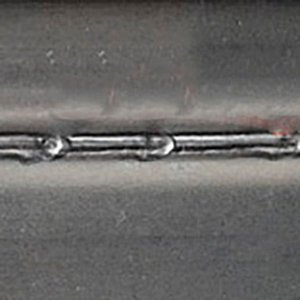

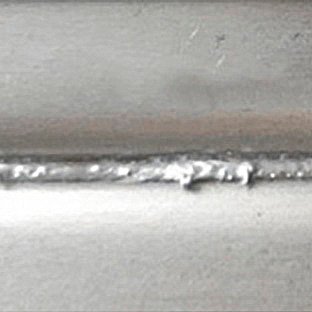

The main objective is to identify defects and imperfections in the weld’s structure and formation, including:

Technology Description

Porosity

Burn-through

Lack of Material

Humps

Cavities

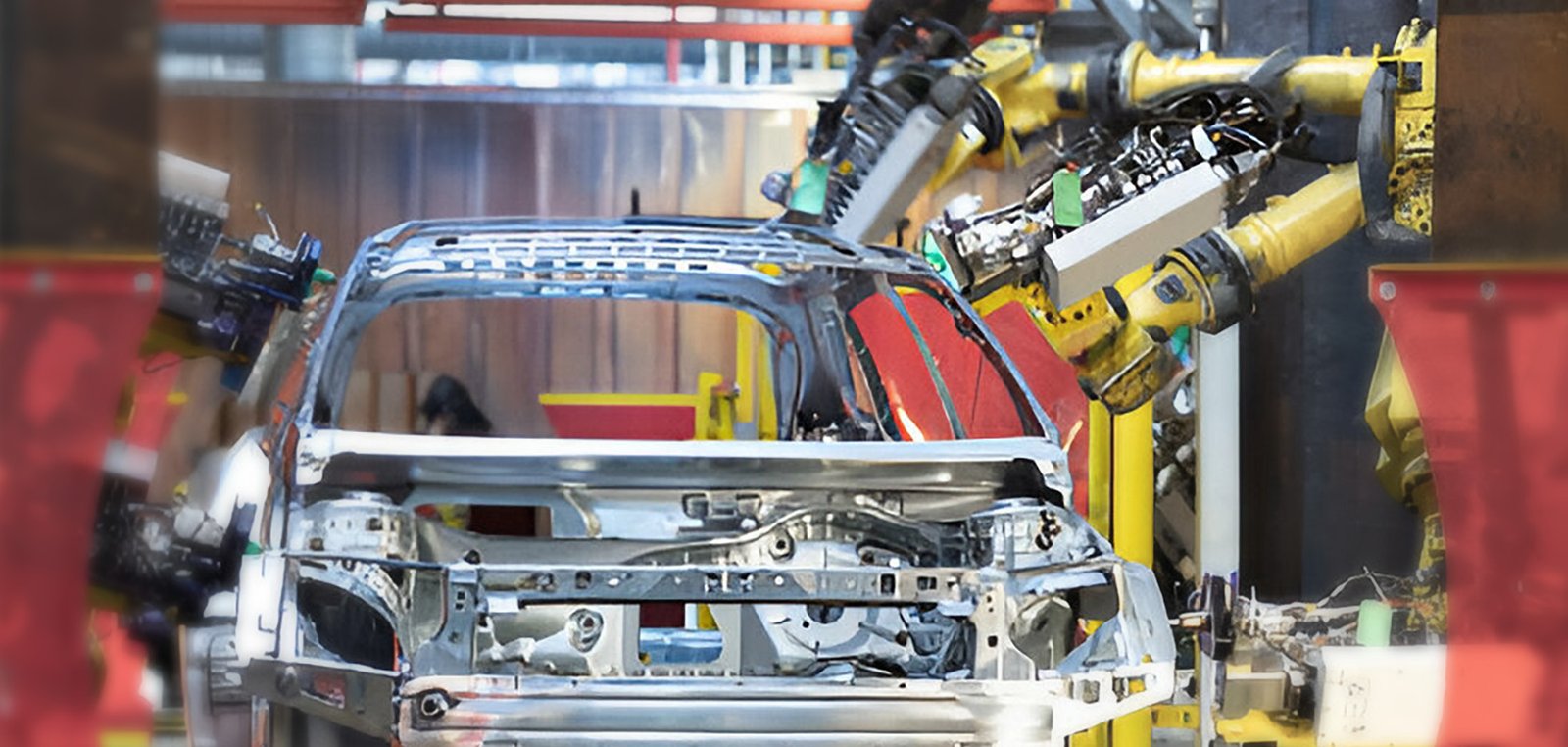

Computer vision applied to laser brazing inspection has become an essential solution for ensuring the quality of joined automotive parts. Vision King utilizes cameras and image processing algorithms to detect defects, irregularities, and specific surface characteristics of the steel that are difficult to identify with the naked eye.

1

Vision King – Coiled Steel and Blanks:

Detects metallurgical defects while the decoils progrides allowing automation to cut defect free blanks.

2

Vision King – Metal Stamping

Detects defects in class A surface right after press operation.

3

Spot Fusion:

Detects weld defects using weld controller data, it can be paired with machine vision to inspect weld aesthetics.

4

Vision King – Laser Brazing Inspection

Visual inspection of Laser Brazing process allowing immediate trobleshooting.

5

Vision King – Adhesive and Sealant

Secure and imediate inspection system that allows operators only dadicate on fixing defects.

6

Vision King – E-coat and Primer

Detects contaminants and defects in e-coated or primed surface allowing operation to focus in fixes before advancing in the production process.

7

Vision King – Base Coat and Varnish

System deditated to inspect for defect on painted surface.

8

Vision King – Final Assembly

Inspects defects in real-time such as missing parts and misalignments under the car.