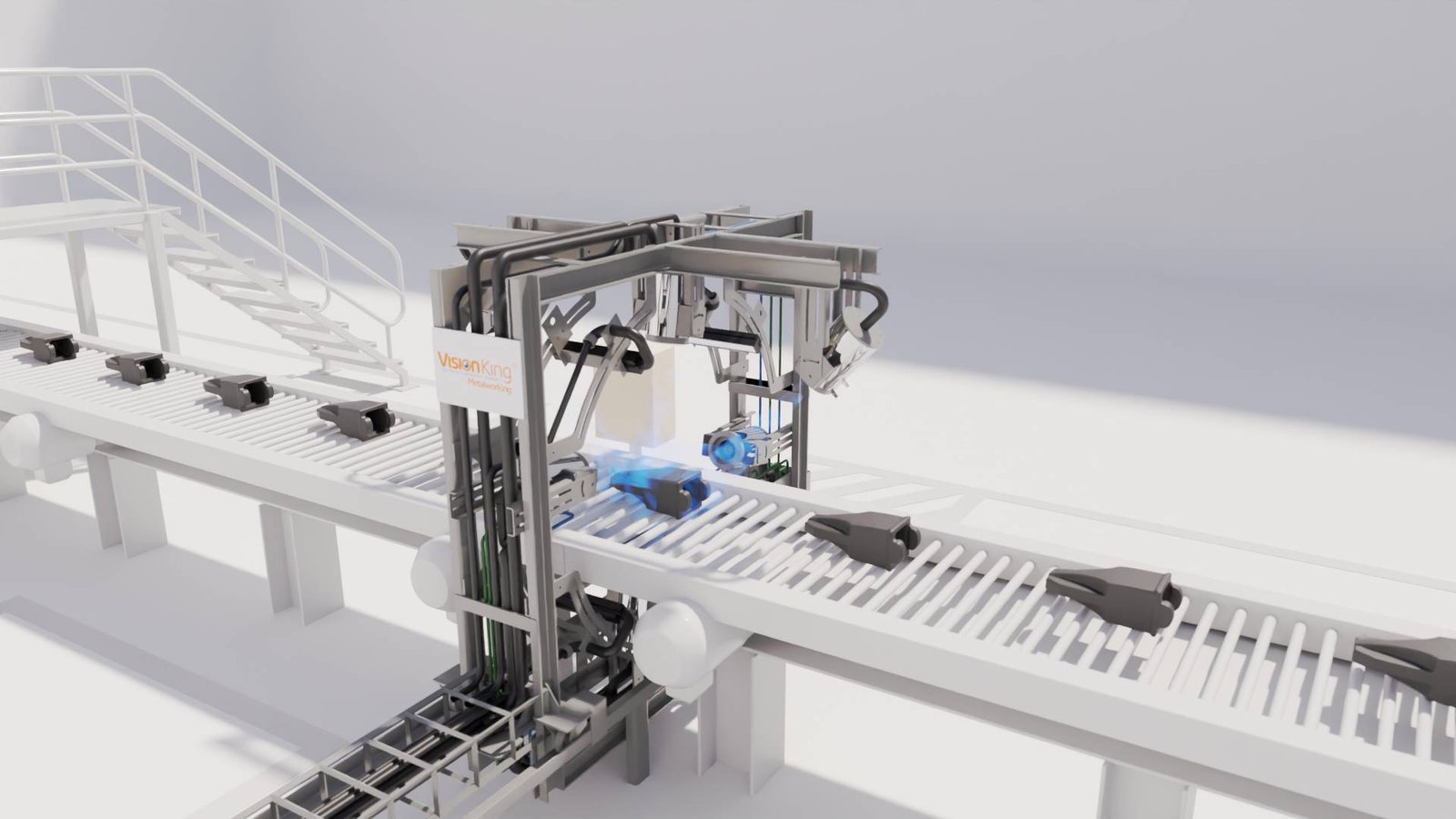

Vision King – Foundry

Technology Description

The primary objective is to identify defects and imperfections in cast steel structures, such as:

Gas Porosity

Shrinkage

Molding Defect

Cold Shut

Metallurgical Defect

Computer vision applied to the inspection of cast steel parts has become an essential solution for ensuring quality in steel manufacturing processes. Vision King utilizes cameras and image processing algorithms to detect defects, irregularities, and specific surface characteristics of the steel that are difficult to identify with the naked eye.