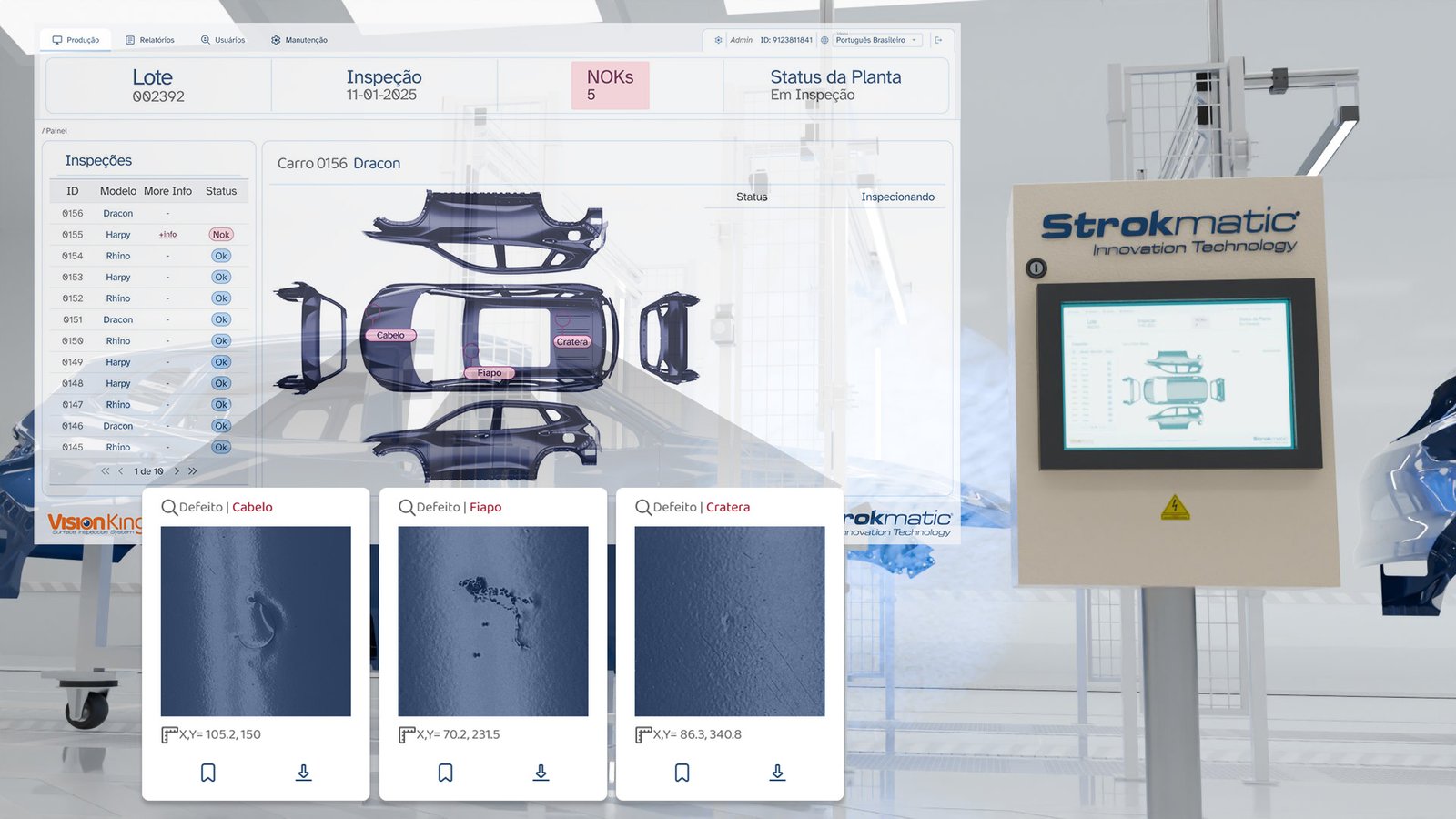

Vision King – Paint Shop

Technology Description

The main objective is to perform precise detection of defects and imperfections in automotive paint and clear coat, ensuring the aesthetic and functional quality of vehicle surfaces:

Scratches

Stains

Dirt

Hairs

Craters

The application of computer vision in automotive paint inspection has become an indispensable solution for ensuring quality in vehicle manufacturing processes. This technology plays a key role in preventing recalls and ensuring end-customer satisfaction by maintaining high aesthetic and functional standards. The Vision King system integrates high-resolution cameras and advanced image processing algorithms to detect, in real time, defects, inclusions, and dirt on newly painted surfaces — imperfections often imperceptible to the naked eye.