Spot Fusion – Spot Weld Inspection

Technology Description

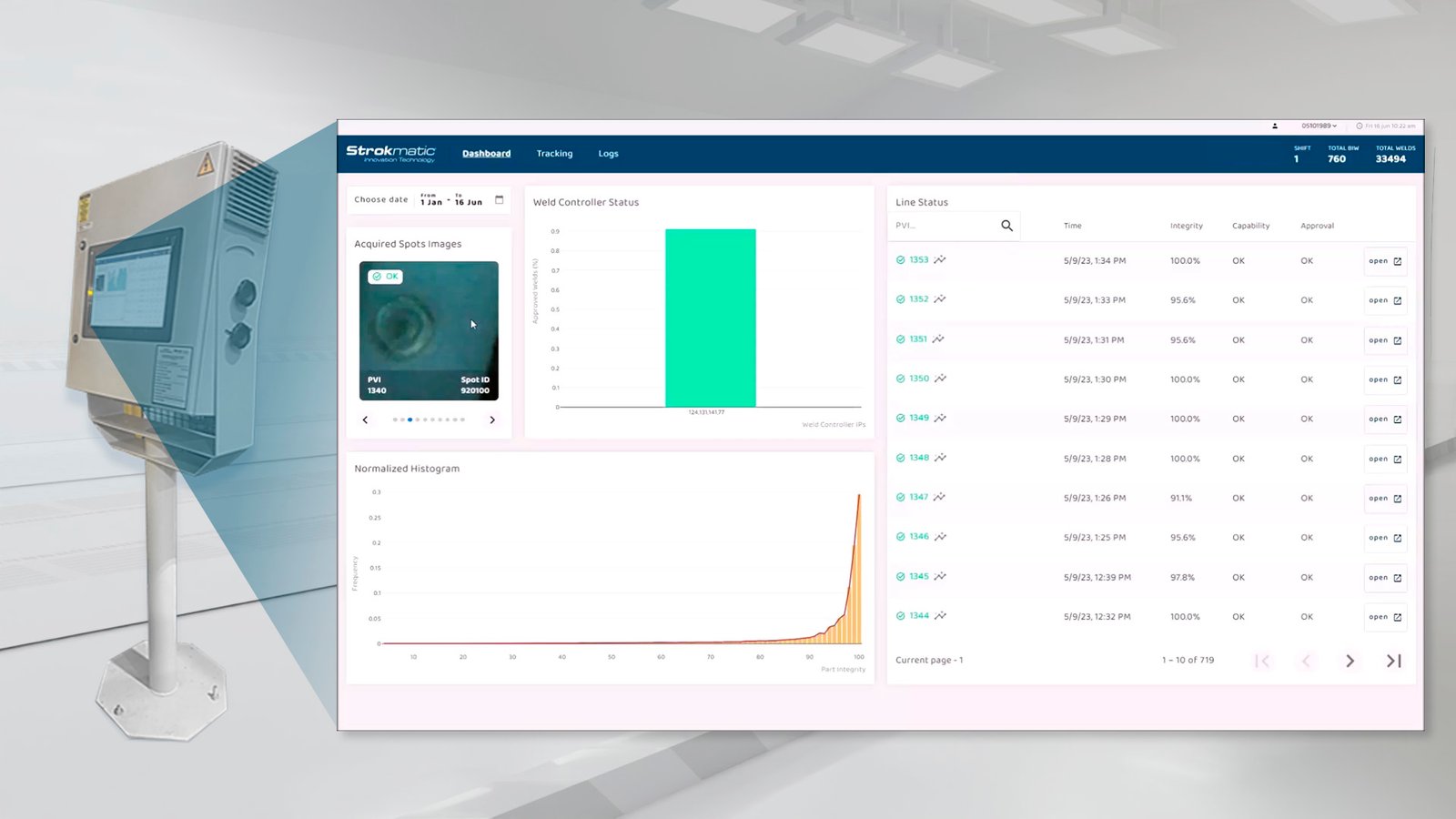

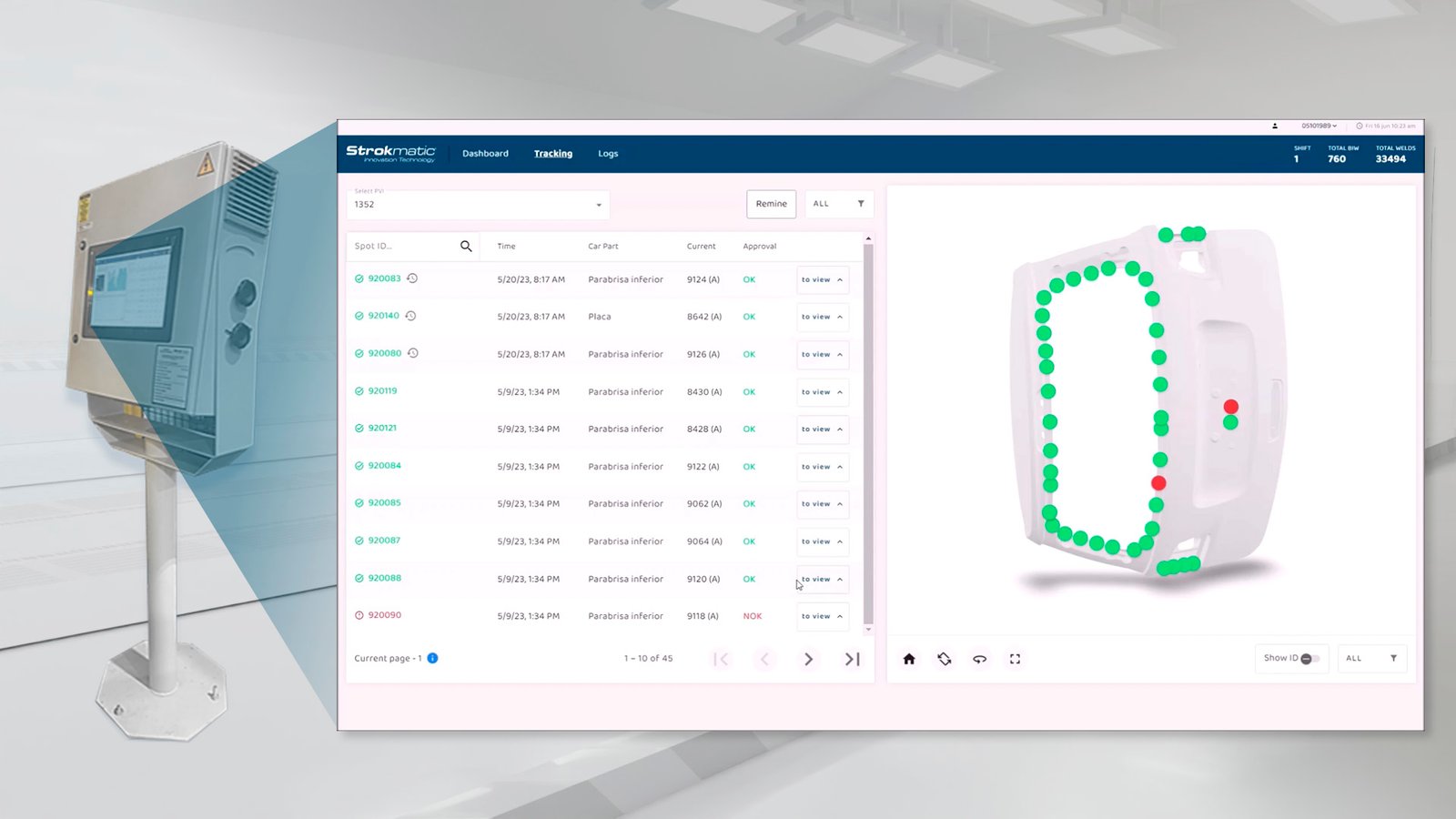

Spot Fusion is a technology developed for 100% inspection of spot welds. It achieves this by analyzing the electrical signatures generated during the manufacturing process and applying artificial intelligence to ensure maximum reliability and precision.

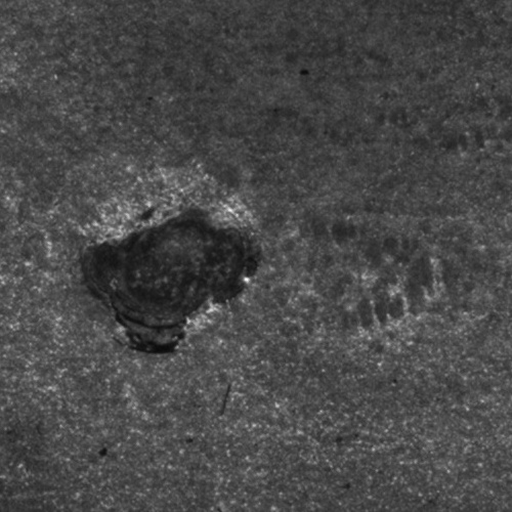

Poorly Executed Weld

(Failed chisel test)

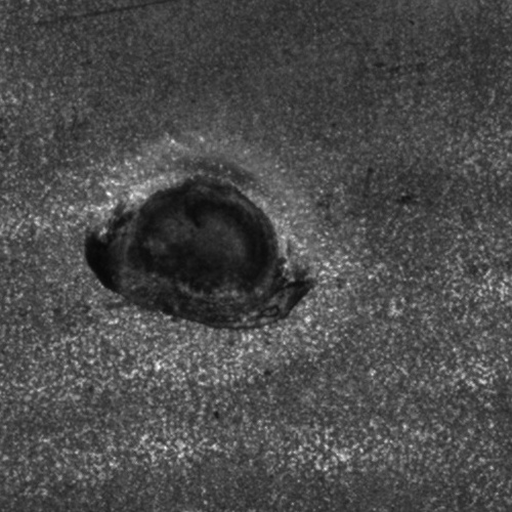

Well-Executed

Weld

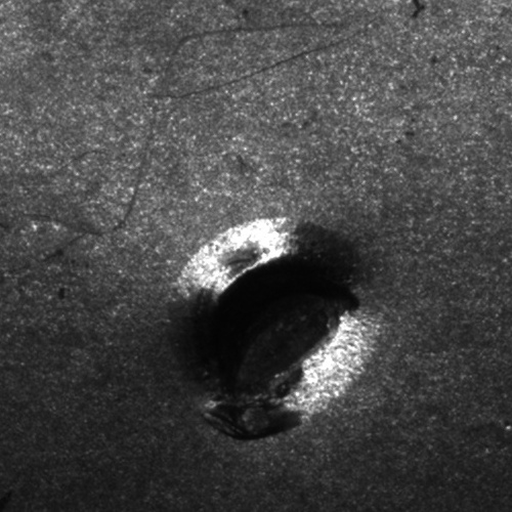

Good Weld, but with

Severe Parameters

Optionally, vision modules can be installed to identify cosmetic defects.

Displaced

Edge

Burrs

Pierced

Missing

With our applied technology, we ensure 100% quality inspection of spot welds, significantly reducing or even eliminating the need for manual inspection. Spot Fusion uses artificial intelligence to monitor the electrical signals of the welding process in real time, automatically identifying potential defects such as cold, missing, or out-of-specification welds. This solution enhances the reliability of the production process, reduces operational costs, and provides complete traceability of all welds performed.